Blog

Embracing Resin 3D Printing: A Complementary Approach to Injection Molding

The world of manufacturing is witnessing a fascinating transformation as two remarkable technologies, injection molding and the burgeoning realm of 3D printing, continue to evolve. However, there’s a new contender on the scene – resin 3D printing. This innovative process is quickly making its mark, particularly in the production of intricate and tailored parts that were traditionally difficult to manufacture through injection molding. In this article, we’ll delve into the landscape of resin 3D printing, highlighting its benefits and showcasing how it harmoniously complements the established injection molding method.

Resin 3D Printing: Advancing Customization and Complexity

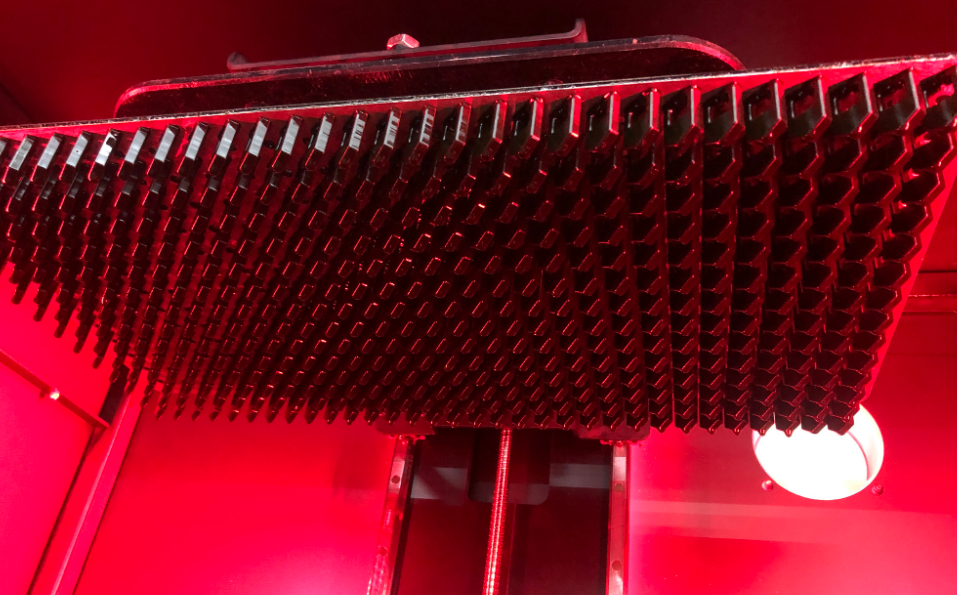

Resin 3D printing, also referred to as stereolithography (SLA) or digital light processing (DLP), represents a pinnacle of precision in additive manufacturing. The process involves layering liquid resin that solidifies upon exposure to light, enabling the creation of intricate, customizable parts that were once deemed too complex for injection molding. Here’s why resin 3D printing is redefining manufacturing in a harmonious manner:

Complexity without Compromise

Resin 3D printing offers the ability to fabricate parts with intricate designs, internal structures, and overhangs that were traditionally challenging or even impractical to produce using injection molding techniques. This becomes indispensable in industries like aerospace and medical, where intricate geometries are prerequisites.

Personalized Precision

One of the hallmarks of resin 3D printing is its exceptional customization. This feature empowers manufacturers to craft unique designs for each product, catering to individual preferences without significantly inflating costs. This is particularly valuable in segments like personalized consumer goods and medical devices.

Accelerated Time-to-Market

The rapidity with which resin 3D printing transitions from design to a tangible product is a significant advantage, especially in industries that demand agility and the ability to iterate designs before reaching the market.

Conclusion

The advent of resin 3D printing introduces a compelling complement to traditional manufacturing methodologies like injection molding. Its ability to foster intricate designs, exceptional customization, and rapid time-to-market serves as a valuable asset in the contemporary manufacturing landscape. Rather than being a competition, the synergy between resin 3D printing and injection molding exemplifies how manufacturing continues to evolve, offering various tools for different production needs. Embracing this harmony allows manufacturers to harness the strengths of both technologies, ultimately propelling innovation and catering to a broader spectrum of manufacturing requirements.