Contact Us | Phone: 833-341-2335

Case Studies

Main Menu

Tools We've Made with Additive Manufacturing

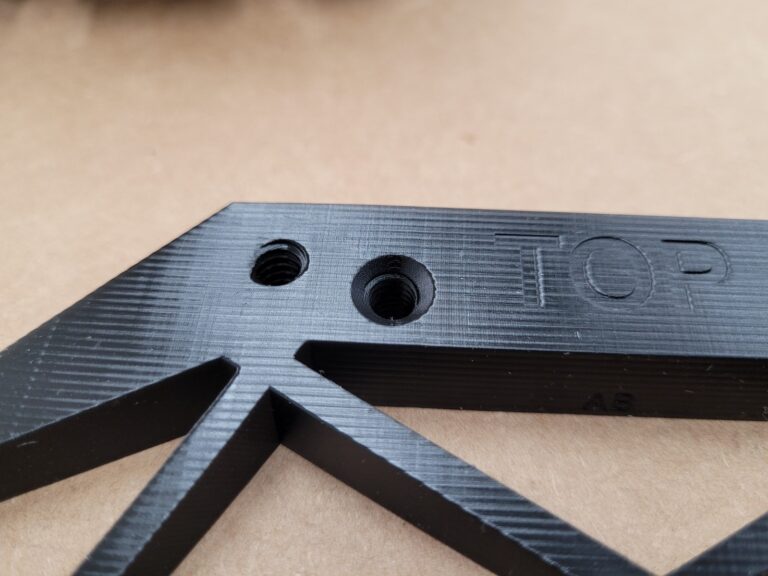

1.1 - EZ Level Crown Master - Crown Molding Jig

Product Details – Are you doing any finish carpentry? Crown Master Wedges allows installers to cut crown molding right side up. The threads are printed into the model so there is no need for thread inserts, a manufacturing success. The old model was produced in China. EZ Level was able to reshore the new model to the United States. This eliminates shipping wait times, tariffs, and expensive design changes. EZ level also didn’t have to buy a mold with us.

Production Rate – Up to 2000 Pieces Per Day

Unit Size – 4in x 8in x 1/2in

Print Time – 16 Hours

Print Resolution – 100 Microns

Units per Print – 60 Units

Material – DL110HB

Printer – Photocentric Magna

Buy yours here https://www.ez-level.com/

“Before, we had to pay $20,000+ for injection molds and had to order thousands! Now, we simply send in our CAD drawings, and the guys at Merit3 go to work, send us back a 3Dversion and once approved… BAM… 2 weeks later we have product! Now, we can order 50 or 5,000 units and our R&D is so quick! Thank you Craig and everyone else at Merit3D for helping us to keep all of our products in the US!!!!”-Brooks Courtney, President of EZ Level

1.2 - EZ Level StudFinder Pro

Product Details – Do you add shelving to walls or do framing after a house has been finished? The Stud Finder-Pro is used to find studs using an evenly distributed magnetic field that creates an 8 inch sweep zone – This previously required more assembly, but is now manufactured in one piece. After printing, 4 neodymium magnets are placed in the 4 holes which will find any screw, nail or metal stud on a wall. It is a very effective way to get the job done and it doesn’t even require batteries like typical stud finders do. Get yours at Ez-level.com

Production Rate -1000 Pieces Per Day

Unit Size – 2in x 10in x 3in

Print Time – 14 Hours

Print Resolution – 100 Microns

Units per Print – 50 Units

Material – DL110HB

Printer – Photocentric Magna

“Working with you through these two designs has been a pleasure. You move quick, you listen, and you deliver. You didn’t give me a 3D version of our product, you gave me ‘artwork’…and that matters a lot to us. You’ve earned the business.” –Brooks Courtney, President of EZ Level

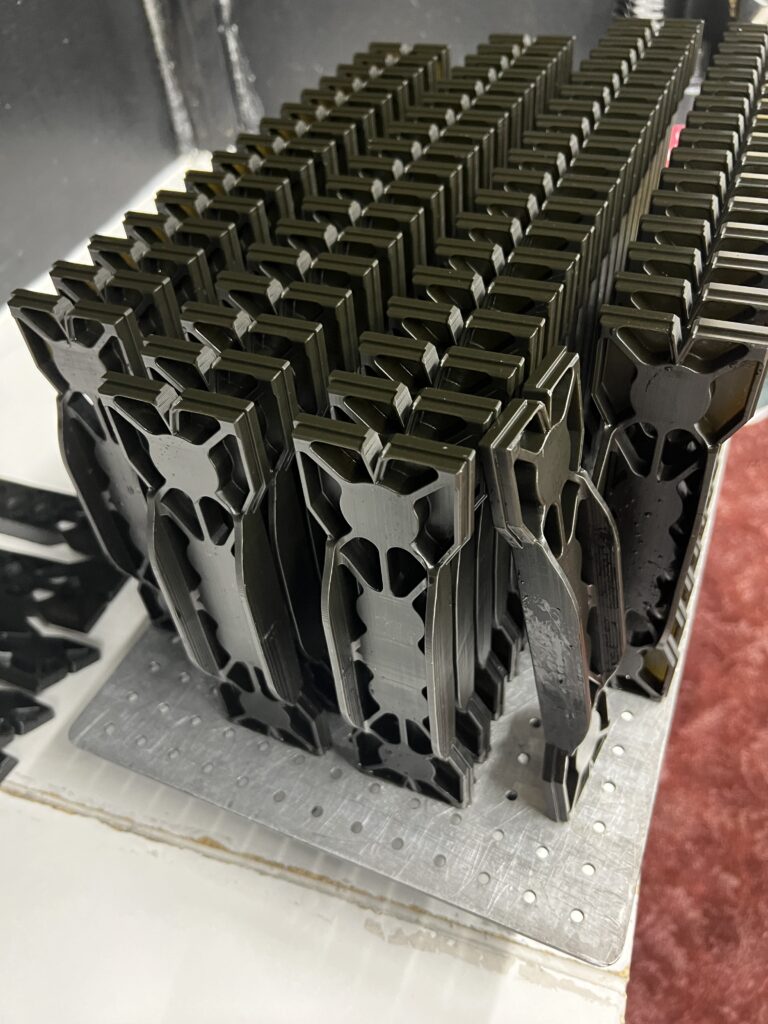

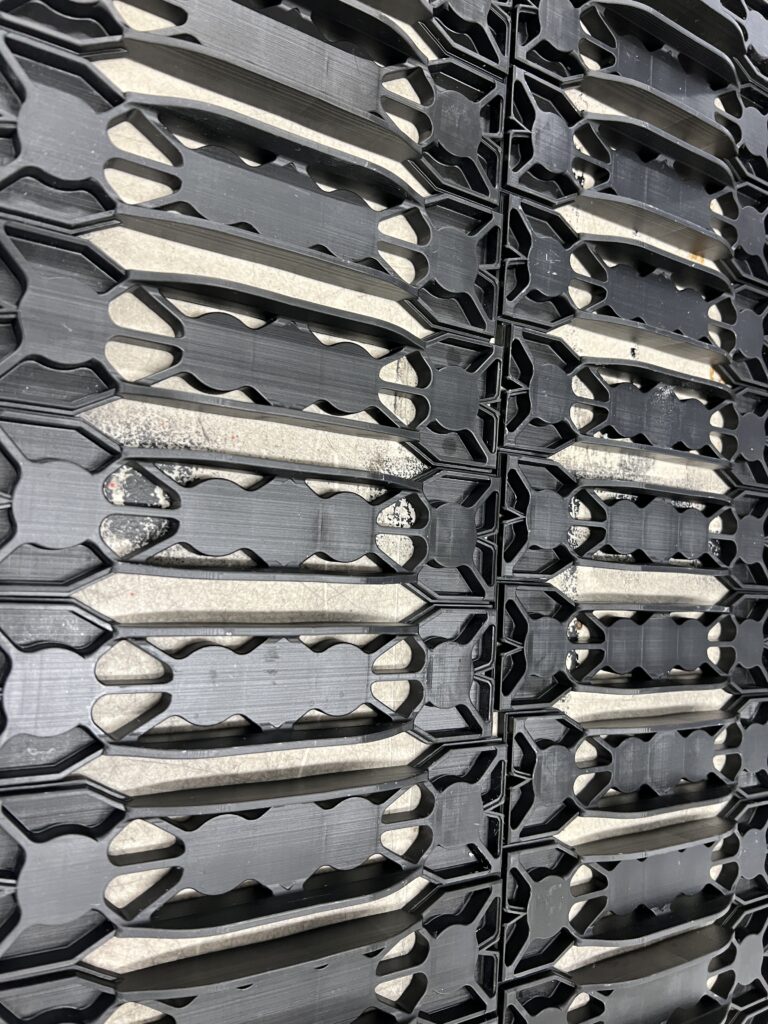

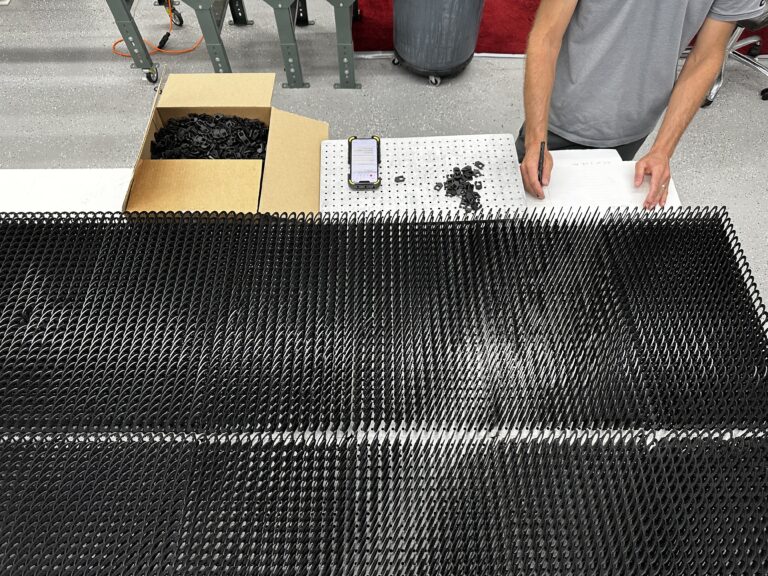

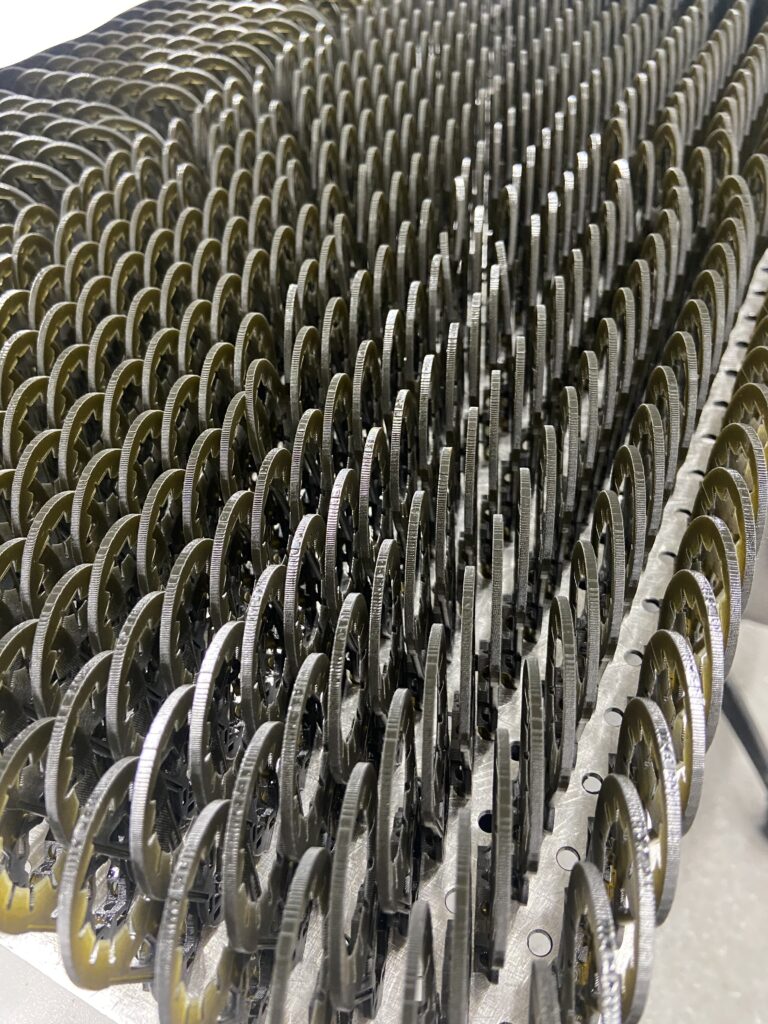

1.3 - Adhesives Technologies Hanger

Product Details – If you have ever purchased liquid products that come in a tube, you’ll have seen something like this. A hanger for epoxy products is a device or component used to attach the mixing nozzle to the epoxy tube in a retail setting. Merit3D is reshoring the production of the hangers bypassing the injection molding process. Adhesives Technology has currently ordered over 1 million hangers from Merit3D. Read about it here.

Production Rate – 24000 Pieces Per Day

Unit Size – 1 1/2in x 2 3/4in x 1/4in

Print Time – 225 Minutes

Print Resolution – 250 Microns

Units per Print – 400 Units

Material – BASF EPD 1006

Printer – Photocentric Magna

“3D Merit saved the day with a critical supply chain issue we were having. They quickly designed a 3D prototype with different materials and features for us to evaluate. Within a few weeks we were able to run samples on the line and provide feedback. Great company which delivers what they say and is very responsive. Great partner!” – Peter Zazzaro DOO for Adhesives Technologies Corp.