Contact Us | Phone: 833-341-2335

Case Studies

Main Menu

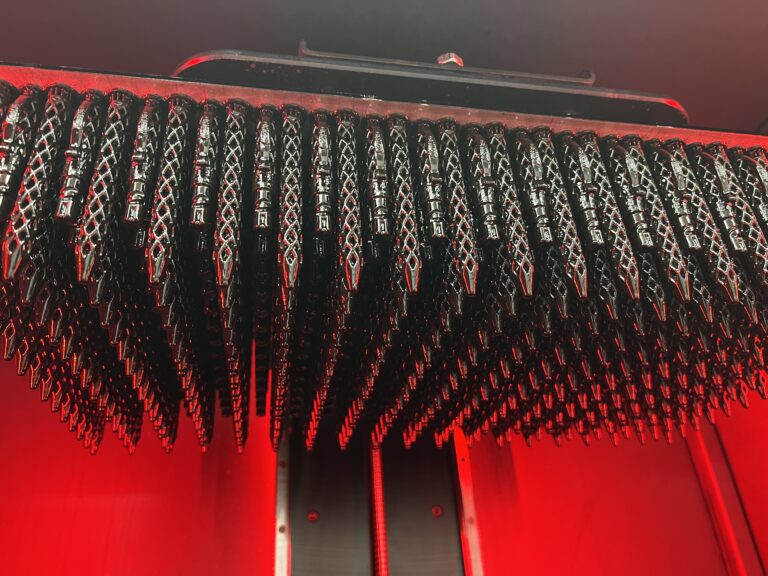

4.1 - Mass-Produced Promotional Pens Made in the US

Product Details -This project was a blast. We asked social media people if anyone could find a promotional pen that was made in the USA and out of the thousands of people looking for pens, no one found one that was newer than 15 years. Bringing promotional products back to the USA again is awesome to see. We are even adding customers logos in 3D to the pens.

Production Rate-5000 Pieces Per Day

Unit Size – Size Of A Pen

Print Time – 6 Hours

Print Resolution – 100 Microns

Units per Print – 400

Material – Any

Printer – Photocentric Magna

“We love taking these pens to trade shows. People walk by and they are amazed to see them. They are more interested in the pens than our own products.” Excited Customer in Cleveland UT. 🙂

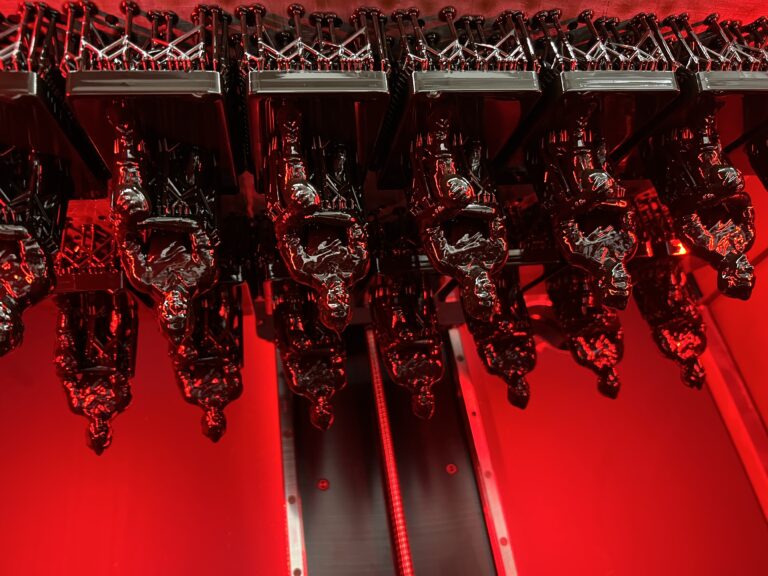

4.2 - Bobby Dodd Trophy for Georgia Peach Bowl

Product Details -The Bobby Dodd Trophy is given out to coaches at the chick-fil-A Georgia peach bowl. We were given the statue and we made some adjustments to the trophy as per the customers requirements. They wanted changes from the original to be an older looking man and also longer arms as per the actual look of Bobby Dodd. The Merit3D team made these changes and the customer was thrilled.

Production Rate-300 Pieces Per Day

Unit Size – 4in x 4in x 8in

Print Time – 10 Hours

Print Resolution – 100 Microns

Units per Print – 12

Material – Duramax

Post process-Painted and clear coated

YouTube video showing detail

Bobby Dodd page link

“We love taking these pens to trade shows. People walk by and they are amazed to see them. They are more interested in the pens than our own products.” Excited Customer in Cleveland UT. 🙂

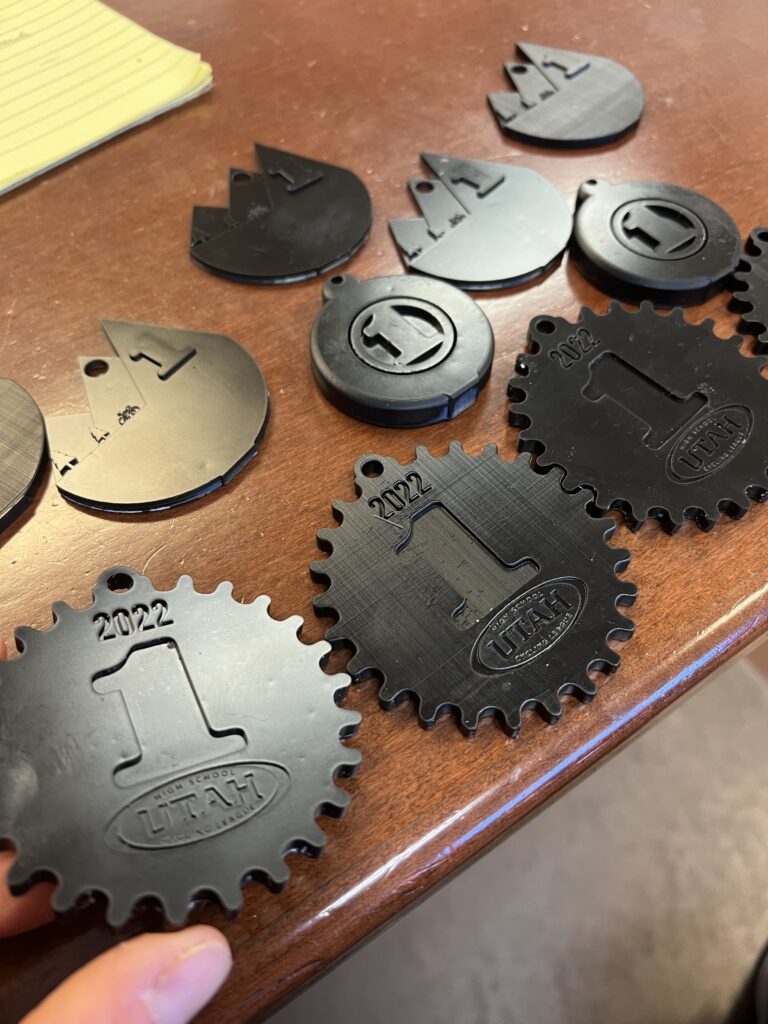

4.3 - Bike Medals for NICA-Utah

Product Details -These medals were printed and then painted for many different positions for NICA races. One of them spins inside it self creating a part that cant be made any other way besides additive manufacturing

Production Rate-5000 Pieces Per Day

Unit Size – 2in, 4in, 6in, 8in, 10in

Print Time – 2hr-6hr

Print Resolution – 100 Microns

Units per Print – 50-300

Material – Any

Printer – Photocentric Magna

4.4 - Fireman Frames- Create frames for those who serve

Order these from http://www.firemanspictureframe.com/ but made here in Utah. These amazing fireman frames are given to retiring fireman.

Production Rate-200 Pieces Per Day

Unit Size – 10in x 6in x 1in

Print Time – 10 Hours

Print Resolution – 100 Microns

Units per Print – 20

Material – many

Printer – Photocentric Magna

4.5 - Trophies - Any shape, endless designs

Unlike traditional trophies and awards, 3D trophies can be made using any geometry then colors added. You can even take a 2D picture and create a 3D file which can then be 3D printed in mass and painted. Black the the color right from the printer then other colors can be added. The longest process is creating the 3D file but once that is done the process for mass production is pretty easy.

Production Rate-1000 Pieces Per Day

Unit Size – 6in

Print Time – 3-8 Hours

Print Resolution – 100 Microns

Units per Print – 50

Material – Any

Printer – Photocentric Magna