Contact Us | Phone: 833-341-2335

Case Studies

Main Menu

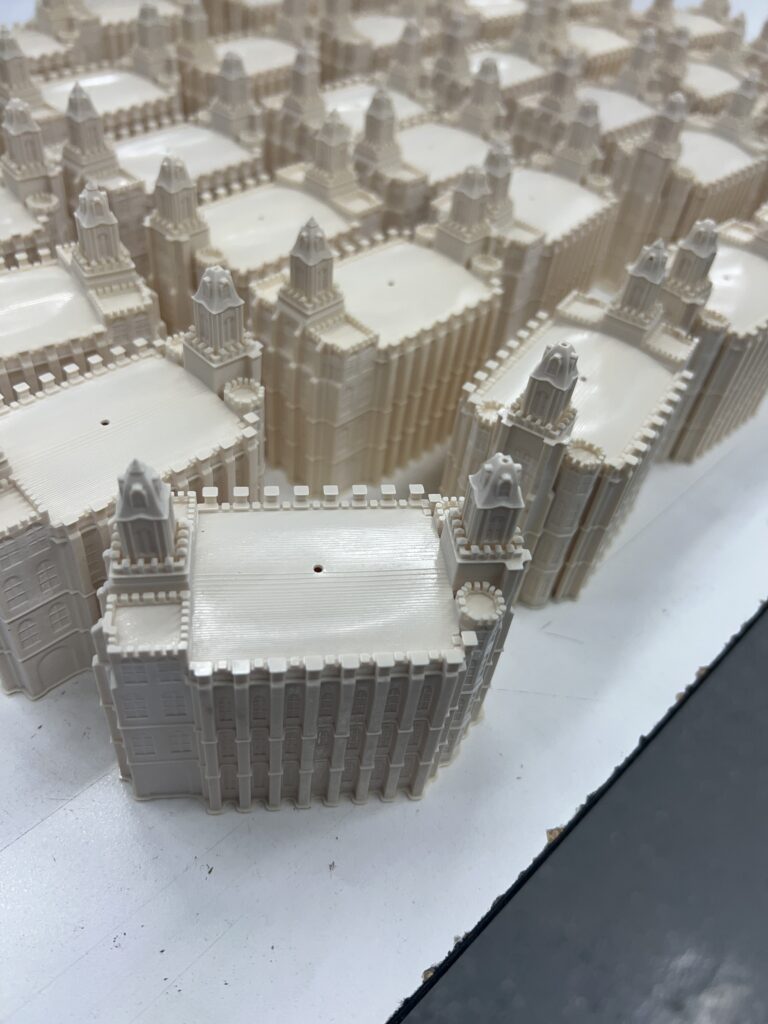

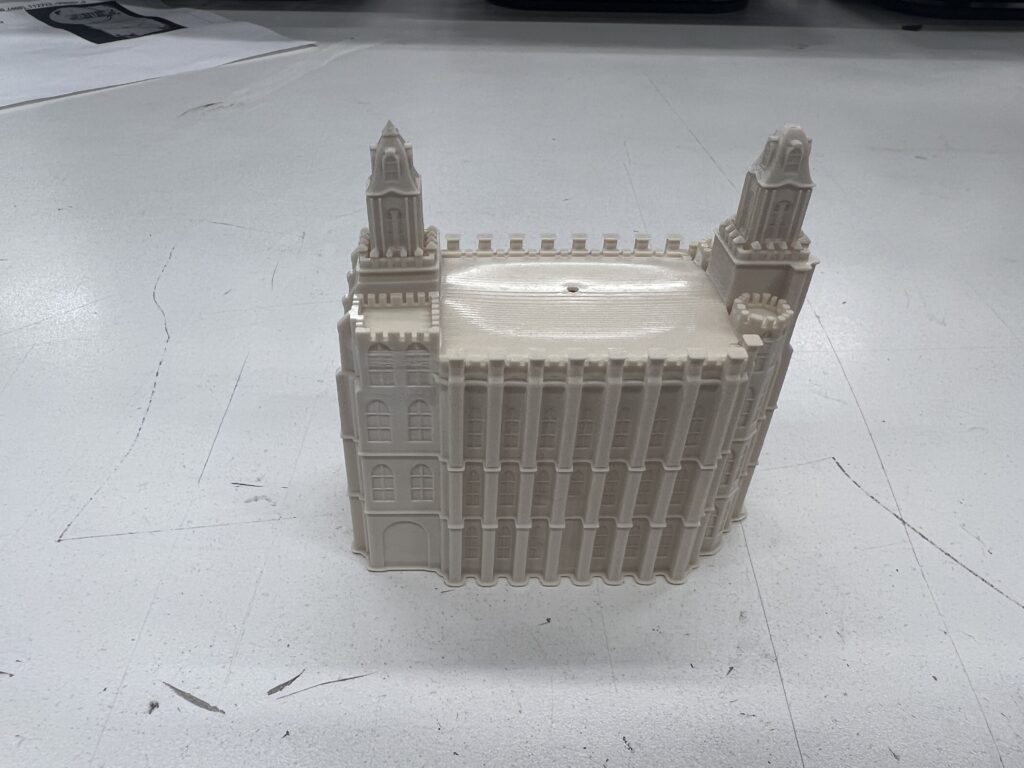

7.1 - Manti Temple night light and Christmas tree ornament

Product Details – The project was done for a ward in the LDS church. They wanted many of these Manti temple Christmas tree ornaments for their kids. Merit3D downloaded a free SLT file then modified it to accept a light in the middle then started printing away. The kids (and Families) Loved them.

Customer- LDS Church

Part Size – 4in x 3in x 2in

Print Time – 3 Hours

Print Resolution -100 Microns

Units per Print -50

Material – Durable Off White

Printer – Photocentric Magna

Cool feature 1- Amazing Detail

Cool feature 2-Hollowed out for internal light

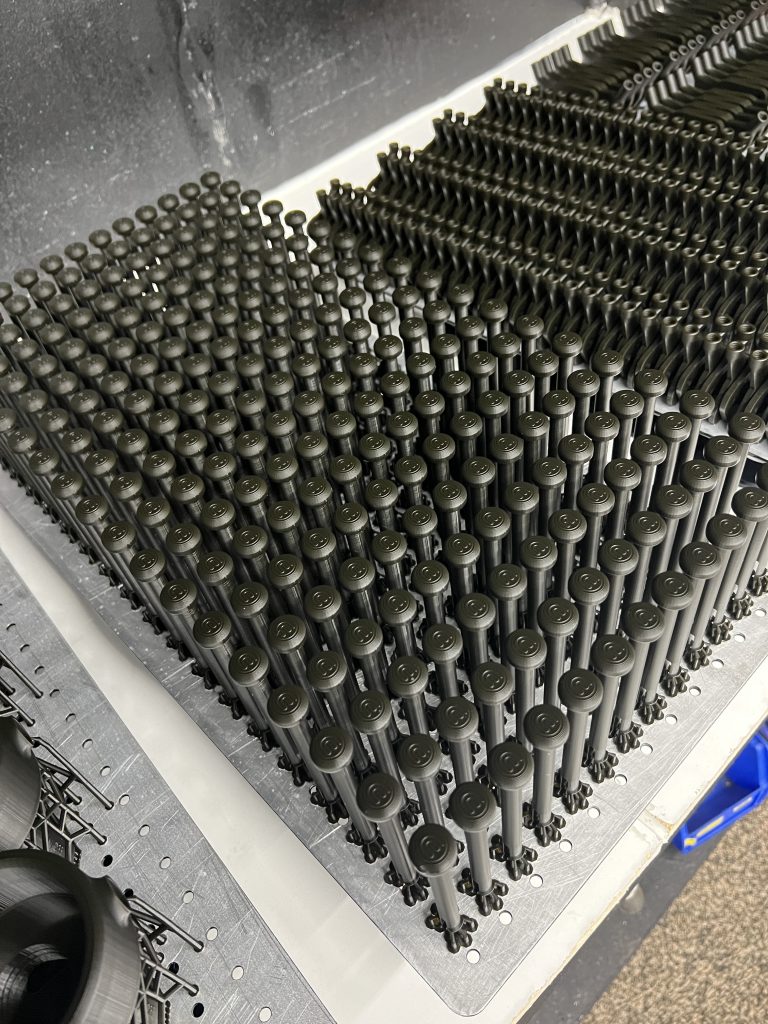

7.2 - Micro screw-watch stand

Product Details -This micro screw was part of a watch stand for a customer. The part turned out well and we were amazed at the detail that we were able to print. The customer ended up combining many parts and eliminated this part but not before we printed 1000 in 15 minutes.

Production Rate- 500,000 Per Day

Unit Size – 1mm x 1mm

Print Time – 15 Minutes

Print Resolution – 50 Microns

Units per Print – 3000

Material – Hard Black

Printer – Photocentric Magna

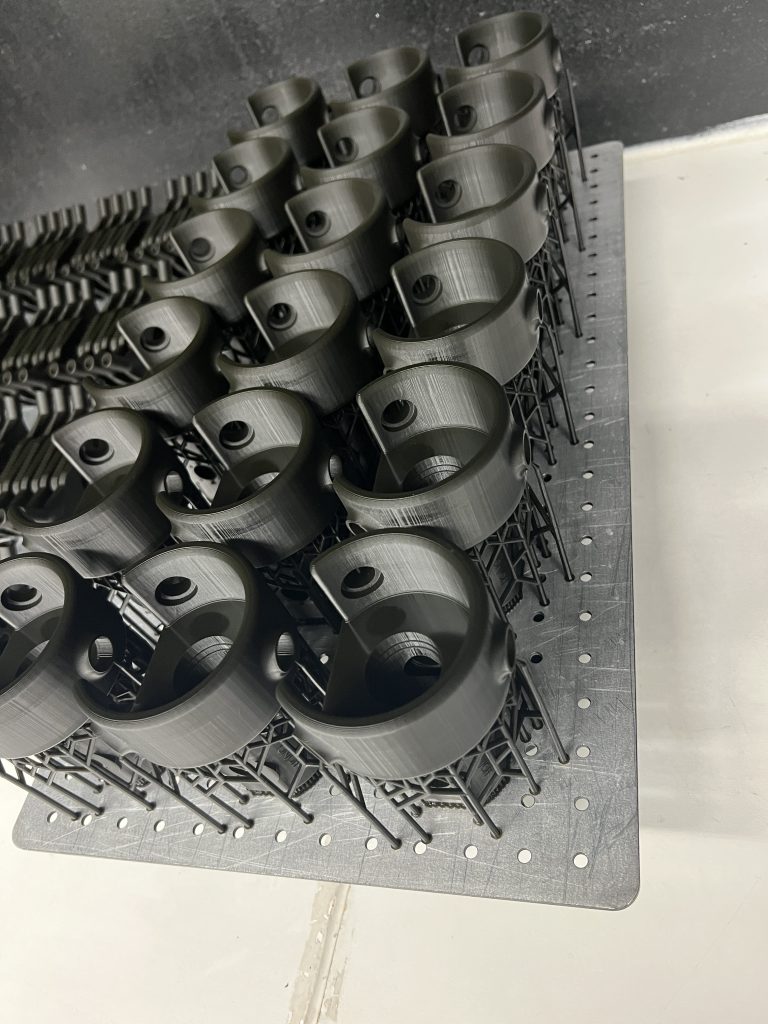

7.3 - HappiOutdoor - Cooler Hinges & Pins

Product Details – This pin was produced in the thousands. It had to have an end that allowed for it to be inserted in a receiving hole. This had many iterations before we perfected the manufacturing process for Happy Outdoors.

Production Rate- 20,000 Per Day

Unit Size – 1/2 in x 1/2 in x 4in

Print Time – 5 Hours

Print Resolution – 250 Microns

Units per Print – 300

Material -Hard Black

Printer – Photocentric Magna

7.4 - PhoneSkope - Scope-Mountable Phone Cases

Product Details -Great relationship with phonescope to the point that they tell us which phones they want their case adapted to and either they send us a design or we design the case from the ground up. This is a great example for additive manufacturing because phones come out every year so making a mold will only last for a few years before you won’t need it anymore.

Production Rate -2000 Pieces Per Day

Unit Size – 3/4in x 4in x 7in

Print Time -6 Hours

Print Resolution -250 Microns

Units per Print -30

Material – DL110HB

Printer – Photocentric Magna

“The work and quick turnaround time is amazing from Merit3D. It has helped us be able go produce cases for the most popular phones to the least popular phones.” Phone Skope

7.5 - Sight In 1 - Tool for sighting in rifle scopes

Product Details – Great reshoring project. Sight in One was working with a company over the water for 2 years before we tried mass producing his part using additive manufacturing. He was amazed at the speed to get to production and had to wait for his boxes to be produced longer than his physical part.

Production Rate- 1000 Pieces Per Day

Unit Size – 3in x 3in x 5in

Print Time – 5 Hours

Print Resolution -250 Micron

Units per Print -30

Material – Duramax

Printer – Photocentric Magna

Cool feature-Threads were put in the part in the printing process so a secondary process was eliminated

“I was working with a company for 2 years in China and Merit3d accomplished more in 2 weeks then we did in 2 years going over seas. THANKS!!!” Tom Lasso-Founder