DO YOUR OWN INFO

This is a page for all additional info relating to the equipment and materials in the “Do Your Own” path.

1. FDM Printers

Bambu Lab X1-Carbon Combo

Technical Data

Bambu Lab A1

Technical Data

Ender-3 V3

Technical Data

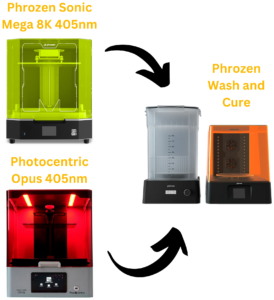

2. Basic Resin Printers

Basic Resin Printer Spec Info

- Phrozen Sonic Mega 8K Specs

- Photocentric Liquid Crystal Opus Specs

- Alternative Cheaper Printer (Phrozen Sonic Mini 8K S)

- Wash and Cure Post Processing

- Links to Purchase and Help Center

Sonic Mega 8K S Specs

System: Phrozen OS

Operation: 3.5″ Touch Panel

Slicer Software: CHITUBOX V1.9.6 and above (or others)

Connectivity: USB

Design: Technology Resin 3D Printer – LCD Type

Light Source: 405nm ParaLED® Matrix 3.0

Release Film: ACF Film

XY Resolution: 43 µm

Layer Thickness: 0.01-0.30 mm

Average Printing Speed: 600 layers/hr

Power Requirement: AC100-240V;50-60Hz

System Power: Max 240 W

Printer Size: L47.2 x W38 x H56.6 cm

Print Volume: L33 x W18.5 x H30 cm

Printer Weight: 26 kg

Photocentric Liquid Crystal Opus

System: Photocentric Studios

Operation: 7″ Touch Panel

Slicer Software: Photocentric Studios

Connectivity: USB, WiFi, Ethernet

Design: Technology Resin 3D Printer – LCD Type

Light Source: 405nm

Release Film: High Tempered Glass

XY Resolution: 81 µm

Layer Thickness: 0.025-0.10 mm

Average Printing Speed: 18mm/hr

Power Requirement: 110-230VAC;50-60Hz

System Power: Max 500 W

Printer Size: L475mm x W415mm x 605mm

Print Volume: L310mm x W174 x H220 cm

Printer Weight: 38 kg

Sonic Mini 8K S Specs

System: Phrozen OS

Operation: 3.5″ Touch Panel

Slicer Software: CHITUBOX V1.9.6 and above (or others)

Connectivity: USB

Design: Technology Resin 3D Printer – LCD Type

Light Source: Linear Projection LED Module

Release Film: FEP Film

XY Resolution: 22 µm

Layer Thickness: 0.01-0.30 mm

Average Printing Speed: 600 layers/hr

Power Requirement: AC100-240V;50-60Hz

System Power: Max 240 W

Printer Size: L47.2 x W38 x H56.6 cm

Print Volume: L33 x W18.5 x H30 cm

Printer Weight: 26 kg

(Spec Information Found Here)

After any SLA 3D print, the parts will need some post processing done before the parts can be considered complete. The post processing consists of removing any supports, washing the excess resin of the part/s, and curing the now clean part.

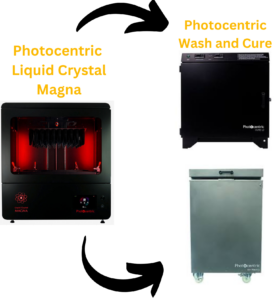

3. Resin Pro Printers

Resin Pro Printers Spec Info

Photocentric Liquid Crystal Magna

System: Photocentric Studios

Operations: 7″ Touch Panel

Slicer Software: Photocentric Studios

Connectivity: USB, WiFi, Ethernet

Design: Technology Resin 3D Printer- LCD Type

Light Source: 460nm

Release Film: Blow Peel and Vat Lift Technology

XY Resolution: 137 µm

Layer Thickness: .025-0.35 mm

Average Printing Speed: 86mm/hr

Power Requirement: 100 VAC – 240 VAC; 50-60Hz

System Power: 500w

Printer Size: L641mm x W852mm x H900mm

Print Volume: 510 x 280 x 350mm

Printer Weight: 110Kg

The Photocentric Wash and Cure station is our recommended tools to post process prints. Some form of wash and cure is needed to achieve a good quality part.

Washing the parts removes all the excess resin from the prints.

Curing the parts finishes the post processing and creates the end use parts.

4. Materials

Choose an appropriate resin for your project. There are a variety of resin manufacturers we partner with for mass manufacturing.

Photocentric: Offers a variety of durable resins tailored for production-grade parts. However they’re not limited to production parts, as they have prototyping and test resins on hand.

BASF: Renowned for its high-performance materials across industrial applications. A global leader of high grade bio-compatible resins.

Loctite: Specializes in high performance engineering-grade resins, providing precision and reliability for diverse manufacturing needs.

Link to all Photocentric Resins

Our Recommended and Most Commonly Used Resins

DL110HB: An incredibly versatile resin that can handle impact, compression, bending and stress fatigue without breaking or deforming.

DL110HTR Smokey Quartz Translucent: Has nearly identical properties as the DL110HB and DL110HW. DL110HTR has the fastest print time capabilities and a unique Amber appearance.

Durable: Creates functional parts that are durable and long-lasting, with high impact strength.

Duramax: Creates functional parts that are very durable and long-lasting, with high impact strength.

DL110HW: DL110HW has essentially identical properties as the black, though requires more finesse.

Flexible DL220B: A newer resin with the key properties of high elongation, impact absorption, efficient energy damping, strong tear strength, and very low water absorption.

Ultracur3D EPD 4006: Ideally suited for making large-scale objects where a hard finish is essential.

Our Recommended and Most Commonly Used Resins

BASF EL4000: Ultracur3D® EL 4000 by Forward AM is the latest addition to our flexible and elastomeric resins.

BASF EL60: Ultracur3D® EL 60 by Forward AM is a very versatile reactive urethane photopolymer for highly elastic applications, combining very good torsional strength and elongation at break with high softness (Shore 75 A) and low water uptake.

BASF ST45: Ultracur3D® ST 45 B by Forward AM are reactive urethane photopolymers for Tough applications that delivers an excellent combination of high strength, plus long-term toughness and impact resistance.

BASF ST80: Ultracur3D® ST 80 W by Forward AM are reactive urethane photopolymers for tough applications.

BASF EPD4006: Ultracur3D® EPD 4006 by Forward AM is an extremely tough and durable material ideal for functional applications.

Our Recommended and Most Commonly Used Resins

Loctite IND475: Tough resin designed for tooling and molding applications, due to its high temperature resistance withstanding up to 230°C and high stiffness.

Loctite 3172: Resin that allows to produce functional parts that require high stiffness with a good surface finish and high impact resistance. Attributes are similar to Polypropylene (PP). This material is resistant to impact stress and is ideal for tooling applications, manufacturing aids, housings and consumer applications such as insoles.

Loctite IND406: LOCTITE IND406 is a tough rigid and durable 3D printing resin that performs well in industrial applications requiring high temperature use. The material offers all-round strength, good impact resistance, and high elongation. IND406 is a great alternative for traditional injection molded plastics such as ABS and PP. Stiffness, toughness, and thermal durability of this material makes it ideal for a wide variety of tools in the production floor and for final parts production.

You can purchase most any resin we use off of MatterHackers’ website.

Build Volume (W*D*H): 256 × 256 × 256 mm³

Nozzle: 0.4 mm Hardened Steel Included

Hotend: All-Metal

Max Hot End Temperature: 300 ℃

Filament Diameter: 1.75 mm

Supported Filament: PLA, PETG, TPU, ABS, ASA, PVA, PET

Ideal for PA, PC, Carbon/ Glass Fiber Reinforced Polymer

Build Plate Surface: Bambu Textured PEI Plate / Bambu Cool Plate (Pre-installed, Random, Both compatible with Micro Lidar)

Max Build Plate Temperature: 110℃@220V, 120℃@110V

Max Speed of Tool Head: 500 mm/s

Max Acceleration of Tool Head: 20 m/s²

Physical Dimensions: 389 × 389 × 457 mm, Net weight 14.13 kg, Gross weight 18 kg

Electrical Requirements: 100-240 VAC, 50/60 Hz, 1000W@220V, 350W@110V

This printer has revolutionized the FDM printer market. It prints very fast and is reliable. The color option is fun but not needed for what we will be mass producing for you.

Build Volume (W*D*H): 256 x 256 x 256 mm³

Hot End: All-Metal

Nozzle: Stainless Steel

Max Hot End Temperature: 300 °C

Nozzle Diameter: 0.4 mm (Included)

0.2 mm, 0.6 mm, 0.8 mm

Build Plate: Bambu Textured PEI Plate (Included)

Bambu High Temperature Plate (Smooth PEI)

Bambu Cool Plate

Max Build Plate Temperature: 100°C

Max Speed of Tool Head: 500mm/s

Max Acceleration of Tool Head: 10m/s²

Supported Filament: ABS, ASA, PC, PA, PET,

Carbon/Glass Fiber Reinforced Polymer

Sensors: Chambering Monitoring Camera, Filament Run Out Sensor, Filament Odometry, Power Loss Recover, Filament Tangle Sensor.

Physical Dimensions: A1 : 385*410*430 mm³ , Package size : 552*532*320 mm³ , Net weight 8.3 kg , Gross weight 11.7 kg

A1 Combo : Package size 546*536*420 mm³ , Gross weight (AMS lite included) 14.3 kg

This is a less expensive option usually under $500. Does not have an enclosure but most times is not needed. Again the color is fun for some things but not needed for what we do.

Build Volume: 220*220*250mm

Input Shaping: Yes (G-sensor included)

Product Dimensions: 358*374*498mm

Leveling Mode: Auto Leveling

Package Dimensions: 541*418*245mm

Display Screen: 4.3″ HD color touch screen

Net Weight: 7.83kg

Mainboard: 32-bit

Printing Speed: ≤600mm/s

Connectivity: WiFi

Acceleration: ≤20000mm/s²

Printable File Format: G-code

Printing Accuracy ±0.2mm

Power Loss Recovery: Yes

Layer Height: 0.1-0.35mm

Runout Sensor: Yes

Filament Diameter: 1.75mm

AI Camera: Optional

File Transfer: USB drive / WLAN / Creality Cloud

Rated Voltage: 100-120V~, 200-240V~, 50/60Hz

Nozzle Diameter: 0.4mm

Rated Power: 350W

Build Surface: PEI flexible build plate

Slicing Software: Creality Print

Nozzle Kit: Quick-swap nozzle (hardened steel tip) integrated with heat-break

File Formats for Slicing: STL, OBJ, 3MF

Extruder: New high-speed direct drive extruder

Supported Filaments: PLA, TPU, PETG, ABS, PLA-CF,

PETG-CF, CR-carbon

Nozzle Temperature: ≤300°C

Heatbed Temperature:≤110°C

The is the most popular 3D printer as of today and the least expensive. It does not have many of the extra features the Bamboo printers have, but it does the trick.