Capabilites

"Any customer can have a car painted any colour that he wants, so long as it is black."

-Henry Ford

The more parts we can print at a time, the cheaper they will cost! More parts at once also means higher quality and faster speed. Our estimates are based on fitting your product onto our 11×20″ printing plate.

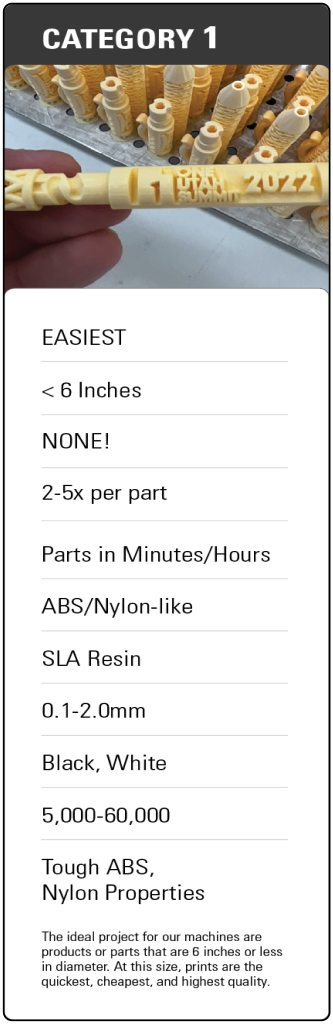

Parts Smaller Than 6"-8"

Ease of Printing

These parts are the easiest and the cheapest to make. We can print thousands of parts like this per day. We have printed up to 62,721 parts in 7 hours and can print up to 100,000 in a 24 hr day.

Cost

These are the parts the compete closely with injection molded piece prices. Usually prices are 2x-5X the cost of IM parts. a $0.50 part would be $1-$2 when 3D printed in mass but without the cost of molds and limitless design changes. 3D material costs are coming down as well so as adoption grows, prices continue to drop.

Colors

These are limited but we can do any color of black that you want. Other colors are off white, amber and transparent. Other colors are coming, and it never hurts to ask if a color you want has been released or is coming soon.

Tolerances

Can vary between 50 microns and 2mm but this is mostly dependent on the design of the part and if it was designed for additive manufacturing.

Capacity

The most parts we have printed so far is 62,000 parts in 7 hours. We then delivered them to the customer that same day. We have many machines to choose from for these smaller parts we can crank parts out. Our Photocentric Magna LOVE to eat through mass production runs.

Materials

We have helped to develop SLA materials that are similar to ABS and Nylon for mass production. Tough-durable parts that compare to injection molded materials, are our specialty.

Machines

We have many types of machines depending on what the application and requirement of the final product of our customers. Some of our printers include LCD/SLA, DLP, FDM.

Resolution

These parts can be super smooth if wanted. Some parts we print have a very glassy surface. We also like putting textures like which are found on injection molded parts. We can change textures with a click of a button.

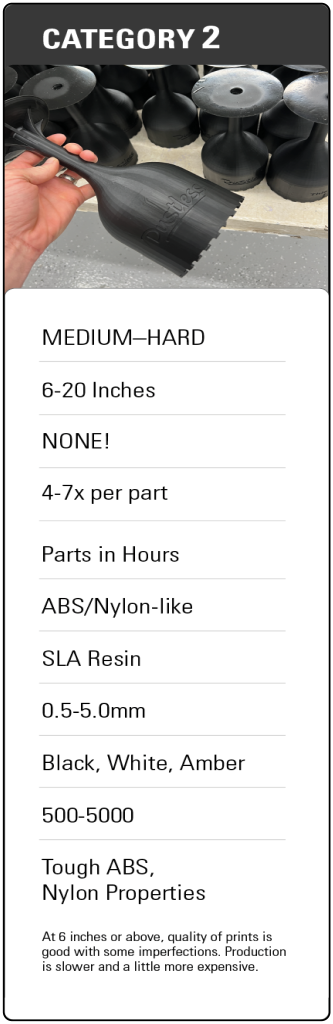

Medium Parts From 6"-20"

Ease of Printing

6 on a scale of 1-10. These parts are not the easiest but once we get a good design, we can print pretty good. Design for additive (DFAM) is more critical with larger parts to print and look good. Larger surfaces tend to warp without proper design. These parts usually take a few more prototypes before the end part looks amazing.

Cost

These parts take longer to print but injection molds could be $100,000. Usually prices are 4x-7X the cost of IM parts. a $4 IM part could be $16-$28 when 3D printed in mass but without the cost of molds and limitless design changes. 3D material costs are coming down as well so as adoption grows, prices continue to drop.

Colors

These are limited but we can do any color of black that you want. Other colors are off white, amber and transparent. Other colors are coming, and it never hurts to ask if a color you want has been released or is coming soon. If a part can be printed using our large format pellet printers, then gray is an option.

Tolerances

Can vary between 100 microns and 5mm but this is mostly dependent on the design of the part, DFAM, and if it was designed for additive manufacturing. Parts that are self-supporting, get much better tolerances compared to parts that need computer generated supports.

Capacity

Parts this size, we can print 500-5000 parts per day on average.

Materials

We have helped to develop SLA materials that are similar to ABS and Nylon for mass production. Tough-durable parts that compare to injection molded materials, are our specialty. If the parts are better suited for our large format pellet printer, then we can print in PP, CFPP, ABS, Nylons.

Machines

We have many types of machines for this size depending on what the application and requirement of the final product of our customers. Printers for larger parts are done using SLA, FDM, pellet printers.

Resolution

SLA parts can be super smooth if wanted. 50-250 microns is common. Some parts we print have a very glassy surface. We also like putting textures like which are found on injection molded parts. We can change textures with a click of a button. If parts are printed on our large pellet printers, then resolution is 2-3mm layer lines and textures are not an option.

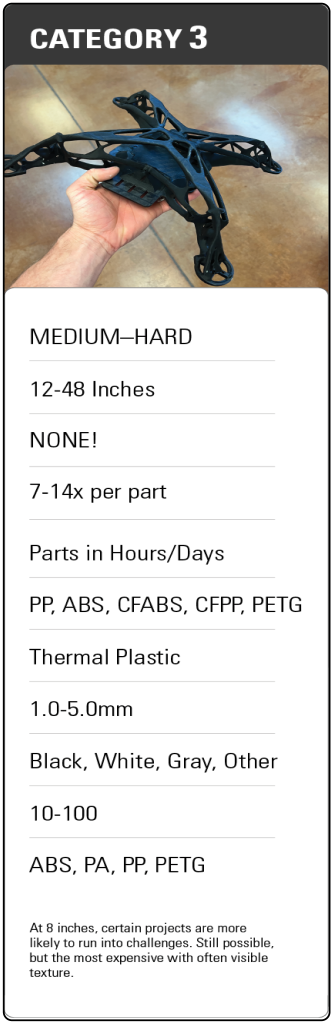

Large & Extra Large Parts From 12"-48"

Ease of Printing

6 on a scale of 1-10. Parts this big are printed with our pellet printers. 2-3mm layer lines are visible. These parts are not the easiest but once we get a good design, we can print pretty good. Design for additive (DFAM) is VERY critical with larger parts to print and look good. These parts usually take a few more prototypes before the end part looks amazing.

Cost

These parts take longer to print but injection molds could be $500,000-$1,000,000. Usually prices are 4x-7X the cost of IM parts. a $4 IM part could be $16-$28 when 3D printed in mass but without the cost of molds and limitless design changes. 3D material costs are coming down as well so as adoption grows, prices continue to drop.

Colors

Gray carbon fiber materials look very good. White, Black and semi clear are common. Other colors are available but usually only an option for large orders as most resins are purchased by the ton.

Tolerances

Can vary between 1mm and 5mm but this is mostly dependent on the design of the part. DFAM helps tremendously to make tolerances hold. If removable supports are required, surface where the supports rough can be a little rough.

Capacity

Parts this size, we can print 10-100 parts per day on average.

Materials

PP, ABS, CFABS, CFPP, PETG, Nylon, flexible and most other materials that can be used in Injection molding.

Machines

Pellet printers with beds up to 4′ x 4′ x 4′.

Resolution

Most parts are printed with nozzle sizes of 2-3 mm. Visible layer lines in 1-2mm are seen. Similar to smaller FDM printers but enlarged. Many times, our customers like the surface finish look of large parts with layer lines visible. Textures are not an option at this time.

Need help? We're here.

Are you ready to get started now? Get a quote, or reach out to us with your questions.